Despite using standard crop production practices, challenges in the growing season can cause crops to suffer. In this Case Study, we examine how custom fertilization strategies (outside of capturing the “low-hanging fruit”) can help maximize yields and increase productivity.

Published January 5, 2024

By: Steve Redmond; BSc

Precision agriculture technology, and its many applications, is fraught with the ongoing question that is at the forefront of every farmer’s mind, and that question is: “Okay, right, but is there a pay back?”. From a technical, and marketing, standpoint we must always question the return on investment (ROI) from an investment in precision ag technology, especially when planning out fertilization strategies.

Some precision ag technology has a clear and simple payback. Autosteer systems with RTK accuracy have changed-the-game for anyone who spends long days in the spring planting, sitting in a self-propelled sprayer for thousands of acres or operates a combine. There is an immediate ROI from reduced crop inputs, such as seed, herbicides, or fungicides and a reduction in fuel consumption as over-lapping is eliminated. Many farmers also observe a reduction in fatigue when using autosteer and this allows them the ability to work longer hours.

This is recognized as an immediate ROI in time saving and in quality of life for the operator.

Applications with a Challenging ROIs:

Now, let’s suppose that we have a precision ag application – such as SoilOptix® – that reveals something; obvious to your crop consultant, but not as evident to you, the farmer/client. The question you will likely ask – sometimes as an objection – is “okay, if I do what you are telling me, will there be any payback and how will I receive a return on the investment?”

West Case Study:

This Case Study examines a common issue SoilOptix® providers face when trying to explain the low-hanging-fruit often apparent to an experienced agronomist, when reviewing the various layers. The best SoilOptix® providers are those with a vast knowledge of healthy soils and balanced fertility, and sufficient field experience to plan fertilization strategies by knowing which amendments and at which rates and application timings to correct the problem.

A field in Western Canada was mapped in spring 2023 and the SoilOptix® Provider, Trevor Thornton with Crop Care Consulting, realized that the real problem was an imbalance in the cations, in particular, calcium and magnesium. The grower had already ordered a pre-blended liquid fertilizer for the barley crop and the fertilizer was on-farm, in storage. This pre-blend was applied using a retail script based on previous yield experiences (or yield maps).

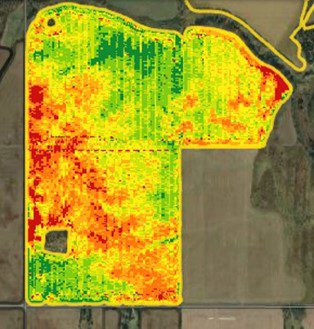

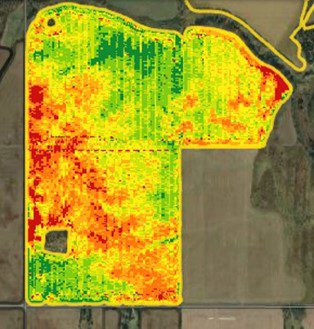

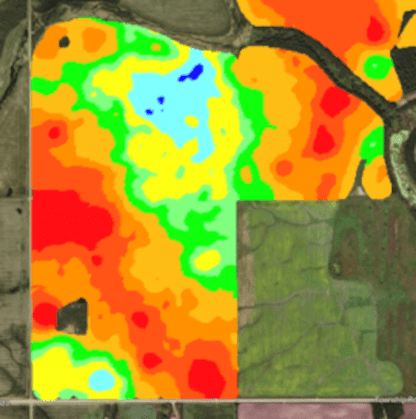

In addition, Crop Care Consulting prepared a prescription for a VRT application of potassium (muriate of potash). This script was applied with the air seeder at planting. The yield map showed a range of barley yield from a low of 7 bushels/acre to a high of 139 bushels/acre.

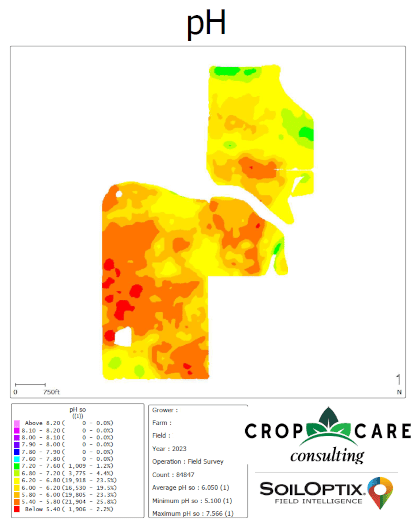

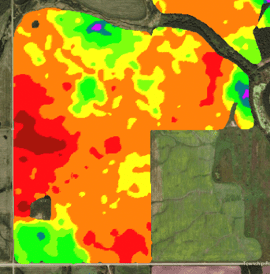

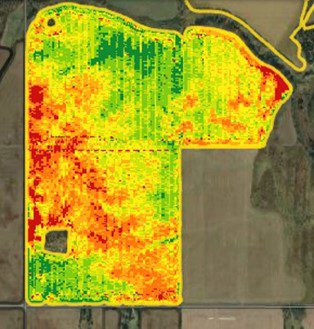

The yield map (Figure 1) showed a pattern that mirrored the SoilOptix® layers for the pH (Figure 2) and the cations (% Calcium and % Magnesium, Figures 3 & 4) that were out-of-balance.

Bottom Line: Crop Fertility is NOT a “Cookie Cutter Approach”

I’m a bottom-line person and love to get to the key learnings.

Despite what may be considered as a “strong” fertilization strategy, after-all the barley crop received sufficient nitrogen, phosphorus and sulphur in correct proportions and the crop also received some potassium at planting, experienced review of the SoilOptix® layers revealed that we missed-the-mark or the “low hanging fruit.”

1.Soil pH – I have been trained (like Trevor), many years ago, to look at three items to indicate the “size of the engine” or how a particular field is expected to yield. In other words, what type of yield potential do we have? Using an automobile analogy, “Do we have a sub-compact car with limited utility, or do we have a Porsche with high end performance?”. The first layer or characteristic I look at is the soil pH. In the West field, the soil pH map has a high correlation to the yield map. Although several composite samples taken from the field indicate that soil pH is not really a concern (6.0 – 7.5 averages), the SoilOptix® layer reveals that we have significant areas with serious pH issues that are reducing yields. The sidebar indicates the ranges below soil pH 6.0. There is approximately 50% of the West field that is below the optimum soil pH level for crop growth. Therefore, we can have a huge impact on yield if we address the soil pH issues in this fertilization strategy.

Side Bar-

Soil pH Ranges Below 6.0

5.80 – 6.00 (23.3%)

5.40 – 5.80 (25.8%)

Below 5.40 (2.2%)

2. Calcium – The % Ca layer indicates that over 80% of the West field is below the optimum level of 75% calcium. This confirms the soil pH layer. We need to fix the soil pH with additions of calcium and the yield potential jumps beyond a sub-compact to a higher performing engine or vehicle.

The role of Calcium – Calcium helps to make plant cell walls stronger, which makes plants more resistant to damage from wind, rain, and pests. Calcium is essential for the development of healthy root systems, and this helps plants to absorb water and nutrients more efficiently.[1]

When calcium is deficient, new tissue such as root tips, young leaves, and shoot tips often have improper cell wall formation causing visual distortion in new growth.

3. Magnesium – I am a broken record on the issue of magnesium and potassium imbalances and this yield limiting problem continues to be ignored by crop consultants without high resolution soil data and the knowledge to recommend the right products at the right rate and right timing to alleviate the impact on yield and quality. On the West field, the fertilization strategy called for the potassium to be addressed by a VRT application at planting, however the % Magnesium SoilOptix® layer shows again that this cation (or lack of this cation) has a high correlation to yield.

VRT N-P-S is a “Cookie Cutter Approach” to Fertilization Strategies:

The West field Case Study shows that, although the farmer is using good crop production practices, standard fertilization strategies, and “industry” recognized rates of N-P-S were applied spatially (VRT application) in 2023, the challenges experienced in the growing season caused the crop to suffer from the cation imbalances. These are the SoilOptix® layers that need to be reviewed with the farmer prior to jumping to a good N-P-K-S fertilization strategy.

The West field is a clear example of why we must pay attention to correcting the cations to maximize the yield of any crop.

West Field – Approach for 2024 Crop:

Crop Care Consulting will have the opportunity – I believe it is underway as I write this Case Study – to discuss with the farmer how to create a fertilization strategy to address the soil pH problem on this field prior to planting a crop in Spring 2024.

In each region of Canada, like other countries, there are different sources agricultural limestone.

Calcitic limestone consists mostly of calcium carbonate and is the most common liming material. Dolomitic limestone is a mixture of both calcium and magnesium carbonates and is used on soils with a magnesium soil test of 100 ppm or less.

Discussions with Trevor at Crop Care Consulting indicate that he is looking at some by-products that can be used as liming materials. The owner of West Field is in good hands with Trevor as he will guide him through the necessary steps to correct the soil pH.

The next time in the crop rotation that this field is planted to barley we would expect that the average yield will take a significant leap thanks to custom fertilization strategies, SoilOptix®, and Crop Care Consulting!

SoilOptix® Service Provider Profile

Trevor Thornton, CCA. P.Ag

Crop Care Consulting

Manitoba, Canada

Trevor is a passionate crop consultant & was the first commercial SoilOptix® Service Provider, coming on board back in 2017. His company, Crop Care Consulting, has since become SoilOptix®’s Western Canadian Distributor, having mapped over 200,000 acres with the SoilOptix® system, and manage a fleet of 4 sensors and 5 subdealers to service Western Canadian growers from British Columbia all the way to parts of Northern Ontario.

You can hear more insights from Trevor’s extensive experiences by watching our Youtube Series, Tech Talks with Crop Care Consulting. We’re also very excited to have Trevor return as a guest speaker at the 6th Annual SoilOptix® Service Provider Forum in February 2024.

Connect with Trevor directly at:

(+1) 204-476-0014

Footnotes:

[1] https://www.pthorticulture.com/en/training-center/role-of-calcium-in-plant-culture

About The Author

Steve Redmond; BSc

Steve Redmond has 35+ years of agricultural experience including crop protection roles in R&D and technical support, seed sales, environmental/nutrient management, soil sampling and fertility recommendations. His experience with Wintex soil samplers, an Aeryon Scout drone, GreenSeeker/Y-Drop applicators and NDVI imagery, VRT seeding and fungicide applications prepared him to enthusiastically embrace the SoilOptix® sensor technology. Now semi-retired, Steve continues to work on projects of interest including “SoilOptix® Agronomy”, balanced nutrition for culinary farms and Irish history.

Connect with Steve: